How I made my own apparatus for the double-slit experiment.

Be aware that if you make one of these devices for yourself you must

follow the manufacturer's rules for laser use (unless you use the

pre-laser method involving a pinhole admitting sunlight into a darkened

room, etc.) because you could burn a

portion of your retina by looking into the beam. You are entirely on

your own. I only explain how I made something for my own use.

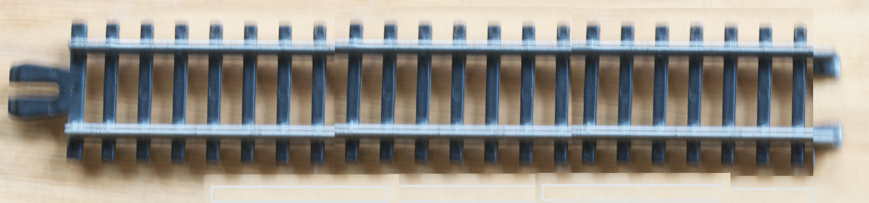

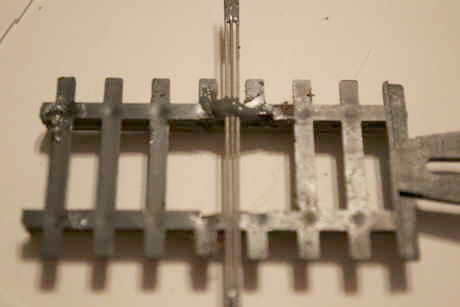

1. I got a plastic railway track section from a toy store. I could have

made a similar frame from chopsticks with a square cross-section.

I found these little track segments in a "dollar store" toy section. I

got a package of several of these plastic units (shown here at about

life size) for one dollar. I was a little surprised to discover how

sturdy they are.

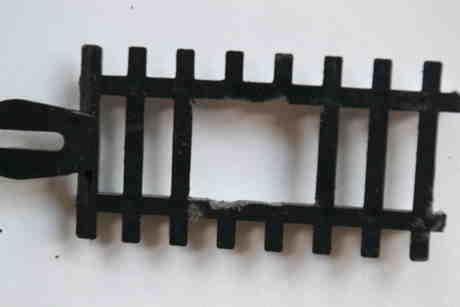

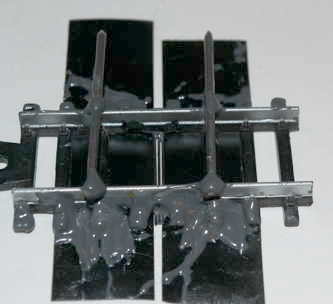

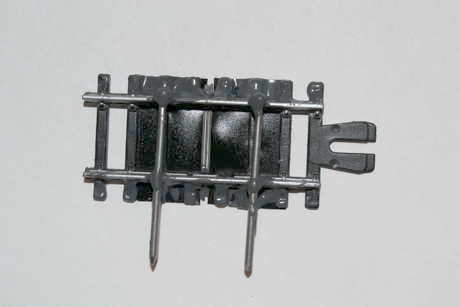

2. I cut the plastic track down to a suitable length.

Only a couple inches of track are needed to make a support for the

double slits, so I cut off a short piece using a fine-toothed hack saw

blade (white painted metal strip shown near the top).

3. I made a rough opening in which to place the bars that will form the

two slits.

I used a steady heavy pressure on the handle of a wood chisel of

appropriate width, which allowed me to cut out

a couple of the "ties," but the cuts were not flush

with the rails.

4. I smoothed the edges of the opening.

It is difficult to find tools small enough to do a perfect job. I used

the same hacksaw blade mentioned above to saw out the little left-over

parts of the "ties" that I cut out with the chisel. A small file would

have done a neater job.

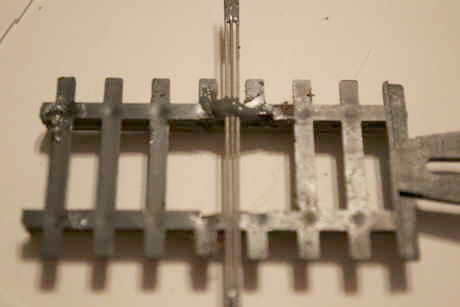

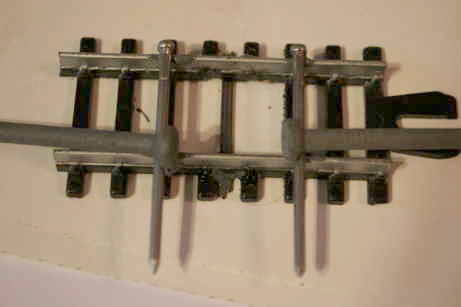

5. i arranged three pieces of automatic pencil lead, and then taped one

end of the

three pieces and fastened them with JB WeldⓇ. In the past I have used

faster-drying adhesives with success.

Getting three automatic pencil leads lined up properly is not easy. All

three must be parallel and they need to have equal spaces between them.

I tried various ways and ended up pushing the ends of the three leads

between adjacent teeth of a comb designed to remove fleas from the

coats of cats. I had to clamp the blue plastic handle of that comb in a

vice to make it hold still for me. Then I held the other ends together

and stuck them to some transparent packing tape. (I had to roll the

tape into a cylinder and put one finger inside in order to be able to

control the pencil leads and the tape with two hands.) Once I had them

in approximately the correct position, I mixed a little JB

Weld

adhesive

and dabbed some onto the ends that were stuck to the tape. JB Weld

takes about four hours to dry, but it is extremely strong and I could

still move things around while it was drying. Other products dry faster

and most should be adequately strong, but JB Weld was what I had at hand

6. I put a dab of glue on the taped end.

It's difficult to see the grey glue on the ends of the leads where they

are held by the tape, but it's there. I made sure to let it

dry

thoroughly before going on to the next step.

7. I taped the other end of the pencil leads and then put a dab of glue

on them.

I next held the leads near the flea comb end and stuck them down to

another cylinder made of transparent packing tape. Following that, I

put glue on that end. At this time I made a few adjustments

necessary to get the spacing between the pieces of pencil lead right. I

could have used slips of

paper to force them farther apart if it had been necessary,

but

this time I got lucky. (The

slits in the device I made are approximately 0.01 inch apart.) Then to

both

ends I applied a fairly large drop of adhesive to stabilize the pieces

of lead in the correct relationship to each other. Because JB Weld

dries relatively slowly I took a look at my project from time to time

just to make sure that nothing had slipped out of place. I wanted to

have a very stable bond once everything was lined up properly, a bond

that would not pop loose somehow and spoil all my efforts.

8. I positioned the leads on the track track and and then put a dab

glue on one end.

I found the part of the three-lead unit that had the best spacing

characteristics, and fixed the unit to one of the horizontal members

with

a dab of

adhesive so that the best part would be within the tracks.

9. I straightened the three-lead units and dabbed glue on second end.

I made my best attempt to line up the three-lead component so that it

was perpendicular to the plastic "tracks." Only then did I put a dab of

adhesive down to join

the leads to the second "track."

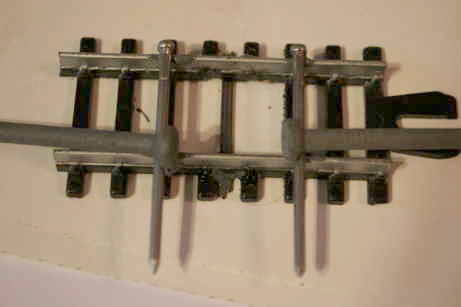

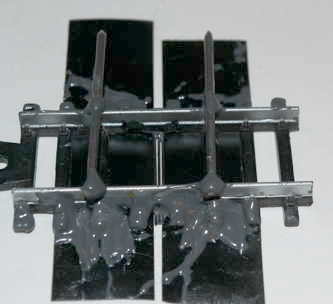

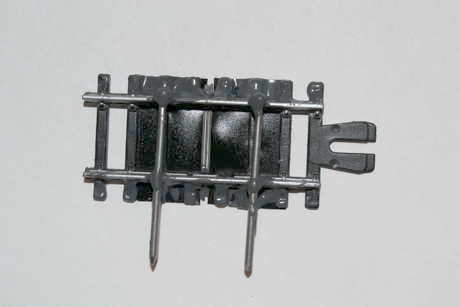

10. I glued both juncture points securely to the track once the

position was idealized.

I appplied plenty of adhesive once the components were positioned

correctly

because I was getting ready to clip the excess lengths of pencil lead,

and I did not want to break anything except the excess lengths. When

the bonds were solid I grasped the pencil leads with a forceps just

inside

inside the part that I wanted to remove. I held the forceps tightly and

snapped

off the unwanted end. then I repeated this operation on the other side.

11. I positioned small nails to act as vertical mounting supports, and

I weighed them

down with larger nails, and dabbed the small nails with adhesive at

their

junctures with the tracks.

I first turned the plastic "railway track" over. I glued two small

nails (about

twice as long as the track is wide) to the

edges of the "window" in which the pencil leads had been glued. They

looked like they might slip around so I weighed them

them down with much heavier nails to keep them in

the proper position while the adhesive was hardening. I tried to make

very sure that the

vertical supports were mounted at 90° to the track before the

glue set. Once I had everything positioned correctly I added

enough adhesive to create a very strong bond.

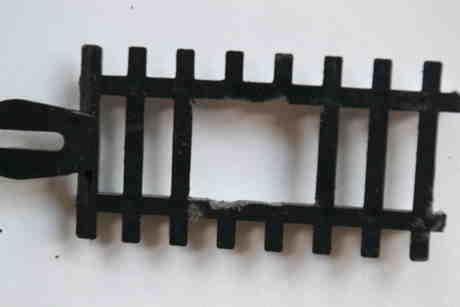

12. I turned the apparatus over again and taped up the open

spaces in

the "window."

It is important to cover the outside pencil leads to their middle

points, but not any further. So I slowly slid the strips of tape from

the

outside toward the inside, and then let them adhere to the tracks when

they had just closed the gaps between the outside edges of the leads

and the large empty spaces in the frame.

13. I turned the whole thing over again and glued this new

tape to the

back side of the tracks, just to be sure it would not come off.

Electrician's tape has good adhesive qualities, providing that the

adhesive surface is not contaminated with powder, oil, etc. However,

having gone to a fair bit of trouble to line eveything up I did not

want the tapes to fall off, so I put

some JB Weld on the back side to try to ensure that the tape

will stay permanently

joined to the rest of this apparatus. It was difficult to get

the

adhesive to go on smoothly, but I was much more concerned to bridge the

gaps between the outside nubs of the "ties" so that the tape would be

attached in an unbroken line all along the parts outside rails.

14. I trimmed off the excess tape and adhesive.

I used ordinary scissors to cut through the tape and the

thick layer of adhesive, leaving the edges relatively even.

15. I made my own arrangements to secure a laser and learn how to use

it safely. All laser devices carry warnings not to look into the beam.

The

reason is that the laser light can burn a hole in your eye, sort of the

way that a magnifying glass can direct the light of the sun onto

something and burn it. I believe in being cautious, so I sometimes use

a pair of special safety glasses designed for the specific frequency of

the laser light. Because the double-slit part of the apparatus I made

is all black I felt it was relatively safe compared to an earlier

version that used shiny brads. Because they were reflective, a beam

from the laser might get bounced directly into my eyes. I

did not want to take chances. I knew that I should not view any beams

coming from the laser itself -- even through the double-slit apparatus.

16.

Once I had turned on and aimed the laser, I saw the interference (shown

in the photo below) projected on a white screen a few feet away.

I viewed this interference pattern on a white matte surface to avoid

the possibility of direct reflections from the laser. (See Laser Safety

on Wikipedia.) Lasers come in different strengths. Anybody who uses a

laser

should

follow the warnings on the laser. On my laser it says: "Laser light is

harmful to eyes! Do not look directly into beam!"

Anyone who wants to make experiments using lasers is entirely

responsibility for their own safety. The author of this page takes no

responsibility for the acts of others, and offers no claim of safety.

To the contrary,

Always take

all due precautions when using lasers. Laser light is harmful to eyes!

Do not look directly into a laser beam!

Number of guests: